Services

Thermal Energy Audit

- Any surface above absolute zero temperature emits infrared radiation which can be measured on infrared spectral band of electromagnetic spectrum.

- Thermography procedure is an extremely easy method of practically monitoring, sensing and recording the surface heating and temperature without touching the surface.

- Thermal camera is used to capture the heat images of surface of objects.

Why should one go for Thermography ?

- Energy Savings: Acknowledging and updating energy inefficiencies automatically reduces a building's demand for energy. An energy audit also increases the building owner's knowledge of operating systems and their proper maintenance, which subsequently further decreases energy usage.

- Financial Savings: Energy savings and financial savings go hand-in-hand. By identifying and committing to strategies that help reduce energy consumption, a building's energy costs can be greatly reduced.

- Increased Occupant Comfort: Indoor environmental quality and overall occupant comfort levels can be raised by simply managing select systems in a building. For example, by upgrading an HVAC system, air flow can be regulated by providing heating and cooling only when necessary. Improved lighting levels can also create a more comfortable atmosphere while reducing energy costs.

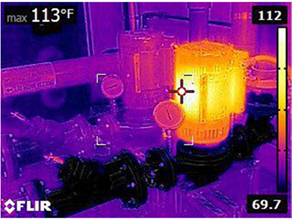

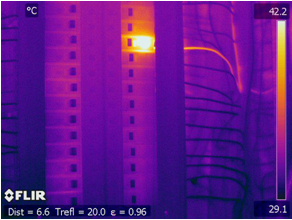

IA offers high end Thermography

- We can detect electrical problems of improper connections, load imbalance, overloads, arching, corona at motors, panels, capacitors, cables, transformers & bus bars through our highly sensitive thermography instruments.

- We can detect thermal/mechanical problems of leaks like air/steam, levels, misalignment, stress corrosion, cracking areas for mechanical utilities such as shaft, pipes, furnaces, blowers, air compressors.

- Thermography only identifies surface temperatures, and we provide analytical reports to determine the reasons for the patterns within the surface temperatures.

Benefits of Thermography Services by IA

- Timely detection of defects & timely rectification.

- Reduction of production losses due to unplanned shutdowns.

- Reduced maintenance and repair costs

- Increased equipment life

- Increased Mean-Time-Between-Failures (MTBF) & equipment reliability

- Increased productivity and profitability

Thermography can detect problems such as

- Switchgear in organization and substations

- Transformers and motor

- Power transmission lines

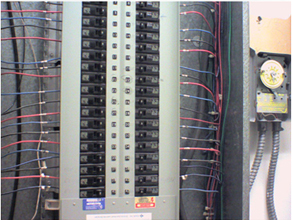

- Distribution panels, circuit breakers and conductors

- Computer and low voltage systems

- Machine control Panel

- PLCs (Valves & Relays)

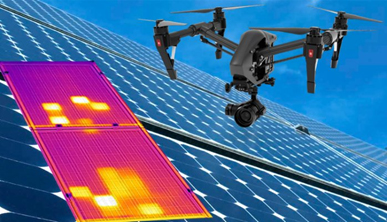

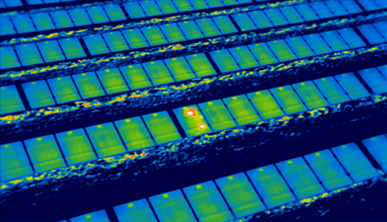

- solar pvc panel and many more

Figure 1air borne solutions for thermal audits

Figure 2 detection of hot spots on solar panels